TO: Director, National Institute for Occupational Safety and Health

FROM: Iowa FACE Program DATE: December 30, 1999

SUBJECT: Two mechanics crushed to death when tow truck falls from jack stand.

SUMMARY

During the spring of 1998,

two male auto mechanics, ages 42 and 48, were killed while working

under the back end of a tow truck. The men were doing routine

repair work on the rear axle and differential of the truck. The

back end of the truck was raised from the floor and supported

by the hydraulic central arm of the wheel lift at the rear of

the tow truck. One jack stand was placed under the central arm

to gain more height. This is a common practice during maintenance

of tow trucks, as the wheel lift hydraulics are both power-up

and power-down, and therefore, are capable of raising the back

of the tow truck. Older wheel lifts had 4-way operation, up-down,

and in-out. This wheel lift was a newer 6-way model, which had

two additional movements, tilt up, and tilt down. The wheel lift

arm was tilted up slightly when the jack stand was put underneath.

The parking brakes were ineffective on the truck because the rear

wheels had been removed after the truck was raised. The front

wheels were not chocked, therefore there was little resistance

to the truck rolling forward. No additional jacks or supports

were put under the truck before the men began work. As the men

worked on the rear axle, they caused the truck to roll slightly

backward. The jack stand slipped backwards off the tilted wheel

lift, and the rear end of the truck fell to the floor, instantly

killing both men underneath.

During the spring of 1998,

two male auto mechanics, ages 42 and 48, were killed while working

under the back end of a tow truck. The men were doing routine

repair work on the rear axle and differential of the truck. The

back end of the truck was raised from the floor and supported

by the hydraulic central arm of the wheel lift at the rear of

the tow truck. One jack stand was placed under the central arm

to gain more height. This is a common practice during maintenance

of tow trucks, as the wheel lift hydraulics are both power-up

and power-down, and therefore, are capable of raising the back

of the tow truck. Older wheel lifts had 4-way operation, up-down,

and in-out. This wheel lift was a newer 6-way model, which had

two additional movements, tilt up, and tilt down. The wheel lift

arm was tilted up slightly when the jack stand was put underneath.

The parking brakes were ineffective on the truck because the rear

wheels had been removed after the truck was raised. The front

wheels were not chocked, therefore there was little resistance

to the truck rolling forward. No additional jacks or supports

were put under the truck before the men began work. As the men

worked on the rear axle, they caused the truck to roll slightly

backward. The jack stand slipped backwards off the tilted wheel

lift, and the rear end of the truck fell to the floor, instantly

killing both men underneath.

RECOMMENDATIONS based on our investigation are as follows:

#1: Vehicles must be properly supported when working under them.

#2: Vehicle repair shops should implement and enforce a written safety program, which includes safe procedures for working under raised vehicles.

#3 Manufacturers, auto/truck shops and tow truck owners should be educated about the hazards of using the wheel lift arm as a support for the tow truck during maintenance and repair.

INTRODUCTION

In May, 1998 two auto/truck mechanics, ages 42 and 48, were killed while repairing a tow truck at a small auto repair shop. The owner of the shop was one of the men killed. Late in the fall of 1998, the Iowa FACE Program became aware of the incident through a fatality summary provided by the Iowa Department of Public Health. Additional information was gathered from newspapers and the local police, who had several photographs of the accident scene. A site visit was conducted in mid-March of 1999 by two FACE investigators and a Graduate Research Assistant.

The small repair shop was a family business and had been in existence for four years since the owner had moved to Iowa with his brother and cousin. The shop was immediately closed after the incident, and it was impossible to visit the site where the accident occurred. However, the owner of the tow truck was close friend of the deceased shop owner, and agreed to meet with us and discuss details of the accident. He operated a towing business in the area, and gave us a thorough demonstration of how a tow truck operates, and how the rear end of the truck can be raised with the hydraulic wheel lift. Several photos were taken during this demonstration.

The owners of the repair shop and the towing company had ridden together several times on towing jobs and the victim (repair shop owner) was experienced with tow trucks and their operating controls. The tow truck owner had three trucks that required periodic maintenance, and the victim was familiar with all three vehicles, having worked on them in the past. However, it is not known how much experience the men had with the repair jobs which required raising the truck as it was done on that day. There was no official safety program at the auto mechanic shop.

INVESTIGATION

The involved tow truck was a 1986 one-ton truck equipped with a hydraulic wheel lift. We did not have an opportunity to see the actual truck, since it had been sold, but from pictures and interviews, it appeared to be in good operating condition. The towing business owned three trucks: two tow trucks and a flat-bed truck. The two mechanics had done maintenance and repair on all three vehicles in the past and were familiar with them. At the time of our investigation the truck owner had purchased a new tow truck, which we observed and photographed. It also had a 6-way hydraulic lift, and was identical in operation to the truck that fell.

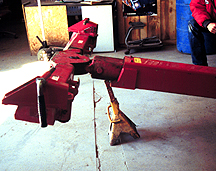

The two mechanics

were repairing the differential gears on the truck rear axle.

The truck was in their shop and was raised using the hydraulic

wheel lift. This wheel lift or "stinger" is used for

securing the wheels of the towed vehicle and supporting it during

towing. There are two types of stingers: 4-way stinger which moves

hydraulically up-down, and in-out, as well as 6-way stinger which

also includes tilt-up and tilt-down as shown in Photo 1. The truck

involved in the injury had a newer tilting 6-way stinger.

The two mechanics

were repairing the differential gears on the truck rear axle.

The truck was in their shop and was raised using the hydraulic

wheel lift. This wheel lift or "stinger" is used for

securing the wheels of the towed vehicle and supporting it during

towing. There are two types of stingers: 4-way stinger which moves

hydraulically up-down, and in-out, as well as 6-way stinger which

also includes tilt-up and tilt-down as shown in Photo 1. The truck

involved in the injury had a newer tilting 6-way stinger.

The shop owner and his cousin had placed a stationary jack stand under the stinger bar, and raised the truck rear wheels by lowering the hydraulic stinger. The stinger hydraulics can easily lift the rear end of the tow truck off the ground. The jack stand was used to raise the back high enough to work underneath. After raising the rear end, the men took off the wheels on both sides, and were working on removing the axles and repairing the differential gears. Both men were working under the truck; the hired man more in the center of the truck and the owner of the shop behind the wheels under the stinger and the rear bumper. The owner’s brother was also working at the site but was not under the truck at the time.

While working on the rear axles the tow truck suddenly rolled backward slightly, slipped off the floor jack stand and fell, immediately crushing the two men working underneath. From police photos one can see the stinger in a tilted position, rear end raised, with the jack stand knocked over to the rear. The rear feet of the jack stand became bent as it tipped over, but the jack stand did not fail or collapse as was first suspected by police. It appears the arm of the tilted stinger simply slipped off the jack stand. There were no additional supports or blocking under the vehicle, therefore the rear end of the tow truck fell flat to the ground crushing the men underneath.

The tow truck was

not damaged in the accident, however the truck was sold since

its owner was friends of both men and he did not wish to keep

the truck any longer. During our visit, he demonstrated the operation

of a similar 6-way stinger. During demonstrations, placing the

jack stand under a tilted stinger bar easily caused the stand

to slip backwards, causing the tow truck to fall to the ground.

The tow truck was

not damaged in the accident, however the truck was sold since

its owner was friends of both men and he did not wish to keep

the truck any longer. During our visit, he demonstrated the operation

of a similar 6-way stinger. During demonstrations, placing the

jack stand under a tilted stinger bar easily caused the stand

to slip backwards, causing the tow truck to fall to the ground.

The floor jack stand used during the demonstration was similar to the one used during the accident. It was 300 mm (12") high in the lowest position and approximately 250 mm (10") wide. From police photos it appears the jack stand was raised to about 380 mm (15") height. The floor jack capacity was approximately two tons according to the tow truck company owner. The truck weighs about four tons, and therefore the jack stand was probably not rated to handle the weight of the truck, however, this does not appear to be a factor in this accident. The stinger was considerably tilted, as shown in Photo 3, which was taken during the demonstration.

The truck engine was not running at the time of the accident, and therefore the hydraulics of the stinger would not have moved. It is possible, but very unlikely, that there was a malfunction in these hydraulics causing the stinger to tilt under the pressure and slip off the jack stand. It is more likely that the workers raised the truck with the stinger in the tilted position. The hydraulic control levers on this truck were on the left (driver) side in front of the rear wheel.

When the rear wheels were removed, the parking brake was ineffective. It is likely that while working under the truck, the men pushed it enough backward so that it simply slid off the jack stand. It is common that the stinger hydraulics are used to raise and lower tow trucks, however, this procedure requires additional support under the vehicle to provide a safe working area. The tow truck owner stated that his friend may have been in a hurry to repair the tow truck, not because of a busy schedule, but simply prompt customer service.

CAUSE OF DEATH

The official causes of death for both men were similar: craniocerebral trauma and basilar skull fractures due to crushing injury.

RECOMMENDATIONS / DISCUSSION

Recommendation #1: Vehicles must be properly supported when working under them.

Discussion: The rear end of the tow truck in this case was supported only by a single floor jack stand, placed in the middle under the hydraulic wheel lift arm. The base of a jack stand is relatively narrow, and is not designed to accommodate any sideways movement of the vehicle without tipping. Apparently the workers were unaware of the hazard they created by removing both rear wheels and not using other supports. The parking brakes were ineffective because the wheels were removed, nor had the front wheels been chocked. Demonstrations using a similar jack stand and similar stinger position showed that very little force or backward movement is required for the stinger to slip off the jack stand. Substantial supports, designed and rated for the

type of vehicle, should be used when working under raised vehicles.

The tow truck owner demonstrated an inexpensive alternative support where two heavy tire rims were stacked and welded together. This support appeared very solid and much less prone to tipping compared to a jack stand. Even with considerable movement of the stinger bar, the vehicle remained safely supported on the welded rims. Yet, even if the vehicle is raised in this fashion, it is still essential that the front wheels are chocked and additional supports of adequate capacity be used before mechanics work under the vehicle.

Recommendation #2: Vehicle repair shops should implement and enforce a written safety program, which includes safe procedures for working under raised vehicles.

Discussion: Auto and truck repair shops should have written safety programs, which describe safe working procedures for hazardous tasks. Working under raised vehicles is hazardous and requires careful assessment as well as use of proper supports. Workers should be trained to follow safe procedures and owners and supervisors should enforce that safe procedures are followed. This auto repair shop was a relatively new small family business. Such businesses may have difficulty developing and following extensive written safety procedures. However, resources are available assisting with establishing safety programs.

Recommendation #3 Manufacturers, auto/truck shops and tow truck owners should be educated about the hazards of using the wheel lift arm as a support for the tow truck during maintenance and repair.

Discussion: Using the wheel lift arm or the stinger appears to be a common method for raising and supporting the back end of a tow truck during maintenance and repair. However, as in this case, it is hazardous unless proper supports are used after the truck is raised. Owners manuals for tow trucks should address this hazard, and education should be provided to auto/truck shop owners and mechanics as well as tow truck owners regarding this hazard.

| ___________________________________ | __________________________________ |

| Wayne Johnson, M.D. | Risto Rautiainen, M.Sc.Agr. |

| Chief Trauma Investigator (FACE) | Coordinator |

| Institute for Rural & Environmental Health | Great Plains Center for Agricultural Health |

| University of Iowa -- Iowa City, Iowa | Institute for Rural & Environmental Health |

| University of Iowa -- Iowa City, Iowa |